Light weight

strong built

Corrosion

resistance

Impact

resistance

Antistatic

Radiolucent

Surface

antibacterial

Scratch

resistant

Moisture

proof

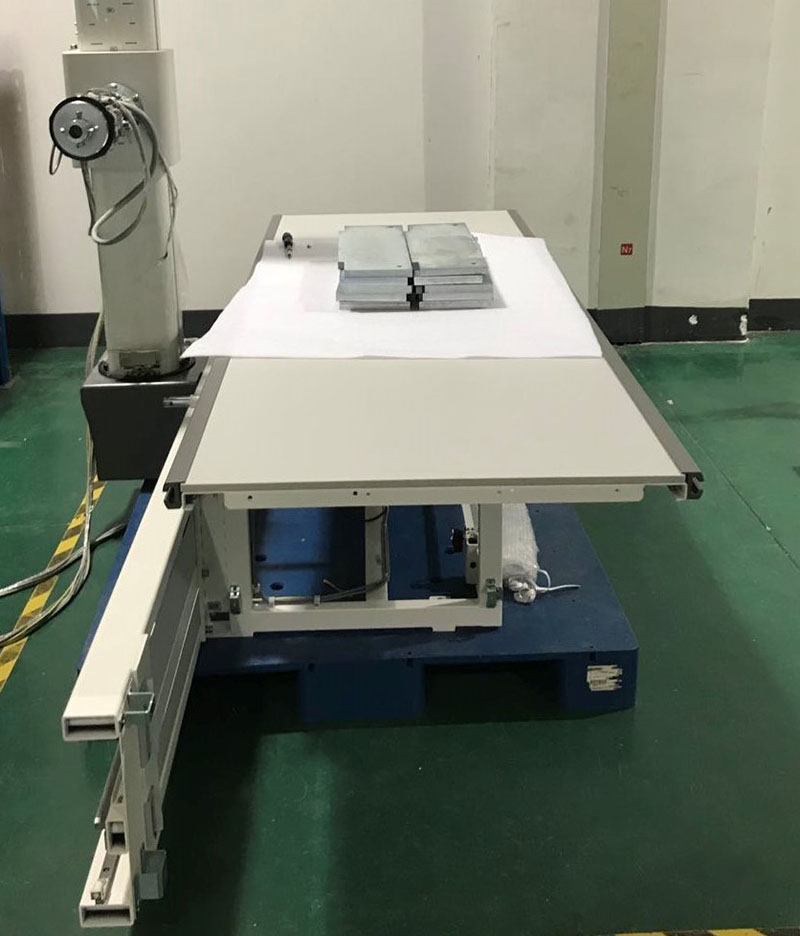

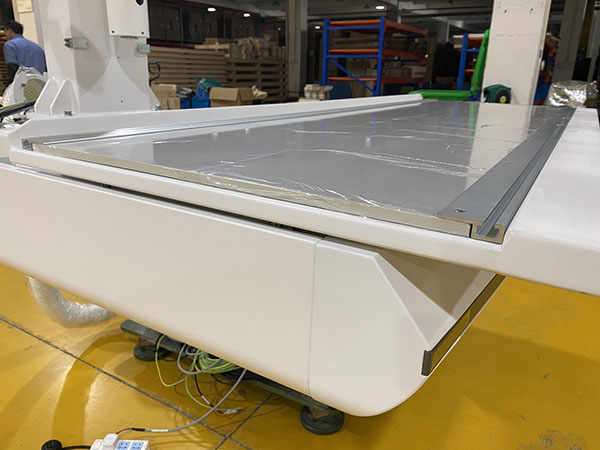

Weadell Composite mHPL Table-Tops is a sandwich structure composite plate, its upper and lower surface using mHPL, core material using special rigid foam. It is the result of systematic improvements to offer the best support for the radiation medicine application. The tabletop overall is lightweight, thin, of high strength, and possess great transradiancy and clean imaging result. Therefore, it is an ideal tabletop choice for all types of X-ray machines.

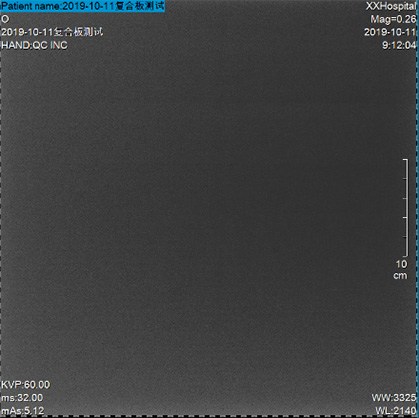

Eligible X-Ray Imaging

Its Imaging results show

• Pure black background

• No spots or blemishes that might interfere with the clinical diagnosis

Making product with these performance is highly related to our raw material selection, process technique and quality control.

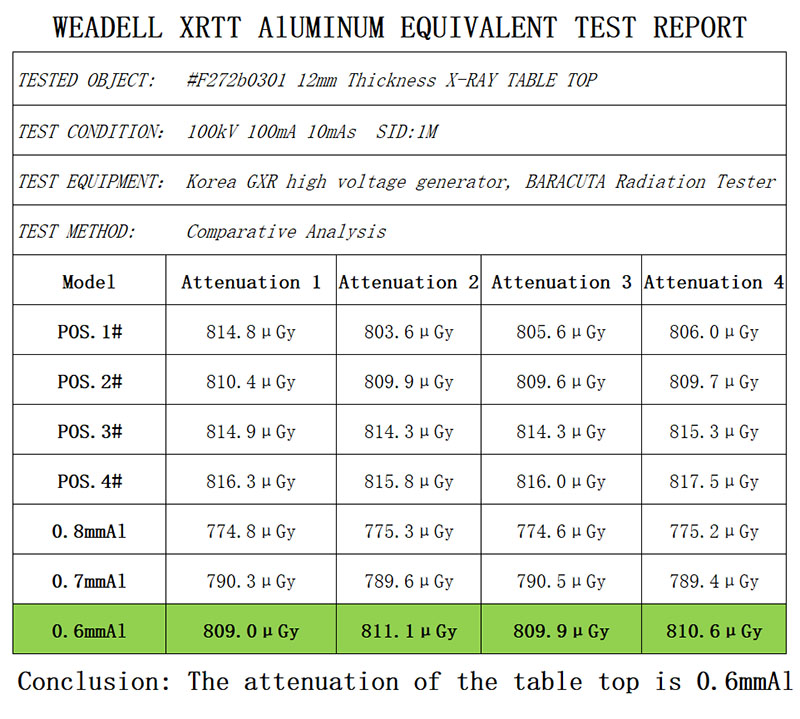

Radiolucent

When x-rays pass through the melamine resin, the material does not block the light, so the attenuation can be low. In other words, it is radiation transparent to x-rays. Using melamine resin as the top boards, radiographic medical system can permit short scanning duration and precise results, can reduce radiation doses, which in turn prevent patients from overexposure.

Lightweight but Strong

Can be made very thin to fit modern design.

Excellent load bearing and impact resistance confirmed by the relevant tests according BSEN438-2/91.

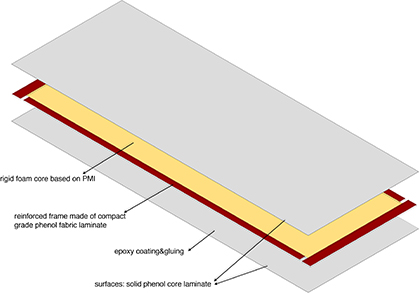

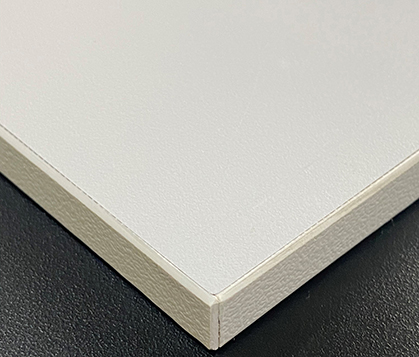

Sandwich construction

• Medical HPL(mHPL) as surface

• Rigid foam based on PMI or close cell PVC as core

• Optional lining edge as structural reinforcement

• Environment-friendly composite adhesive

Rigid foam core based on PMI

• Low density ensures excellent transradiancy

• Excellent strength to weight ratio

• A variety of specifications density optional, flexible adjustment and customization

Special embedded nut

The insufficient holding force of composite is a common problem. But do not worry about that, we can pre-install special built-in nut, to ensure that the product can be dis- and assembled many times.

End edges with PVC-band

• High quality PVC material

• Automatic Banding machine guarantees the sealing quality

The thermoset structure, with the solid phenol core and the melamine surface, provide the panel very strong mechanical performance, which is confirmed by the impact test, according BSEN438-2/91, measuring the degree of depression after a sphere hit.

Special surface structure, so that the melamine surface has scratch resistance, even against a variety of hard objects can also maintain long-term undamaged.

The test of BSEN438-2/91 proved that the melamine plate has strong wear resistance and is suitable for places where heavy objects are placed or places where frequent cleaning is required.

The tight, non-permeable surface makes it difficult for dust to adhere to it, so the product can be easily cleaned with the relevant solvent without any damage on surface.

Melamine board core uses special thermosetting resin, so will not be affected by weather changes and moisture, will not decay or produce mold. Its stability and durability is comparable to that of hardwood.

The test of bsen 438-2/91 showed that the surface of melamine plate has strong protection ability against burning cigarette. The material is flame retardant, the panel does not melt, Drip or explode, and can maintain its properties for a long time. Various European tests have shown that the material has a high level of fire resistance. In France, the material is rated F1 for its non-release of toxic and corrosive gases, as shown in the melamine plate test NFX70100 and NFX10702, it’s one of the best materials for construction. In China, melamine plate by the National Fire Materials Testing Center, its combustion performance GB8624-B1.

According to DIN51953 and DIN53482, melamine plates can be produced as anti-static materials, which makes the plates very suitable for dust-free areas such as hospitals, pharmaceutical factories, food industries, electronics industries and optical and computer industries.

Physical and chemical plate has strong chemical corrosion resistance, such as: acid, oxidation of toluene and similar substances. Melamine plate can also prevent disinfectants, chemical cleaning agents and containing food juice, dye erosion. They will not affect the properties of melamine plate, also will not affect the surface, for the frequent use of strong acid, we recommend the use of high-strength anti-chemical properties of the physical and chemical plate.